A modular and reversible new building for the fire station and the P+R site in Marly

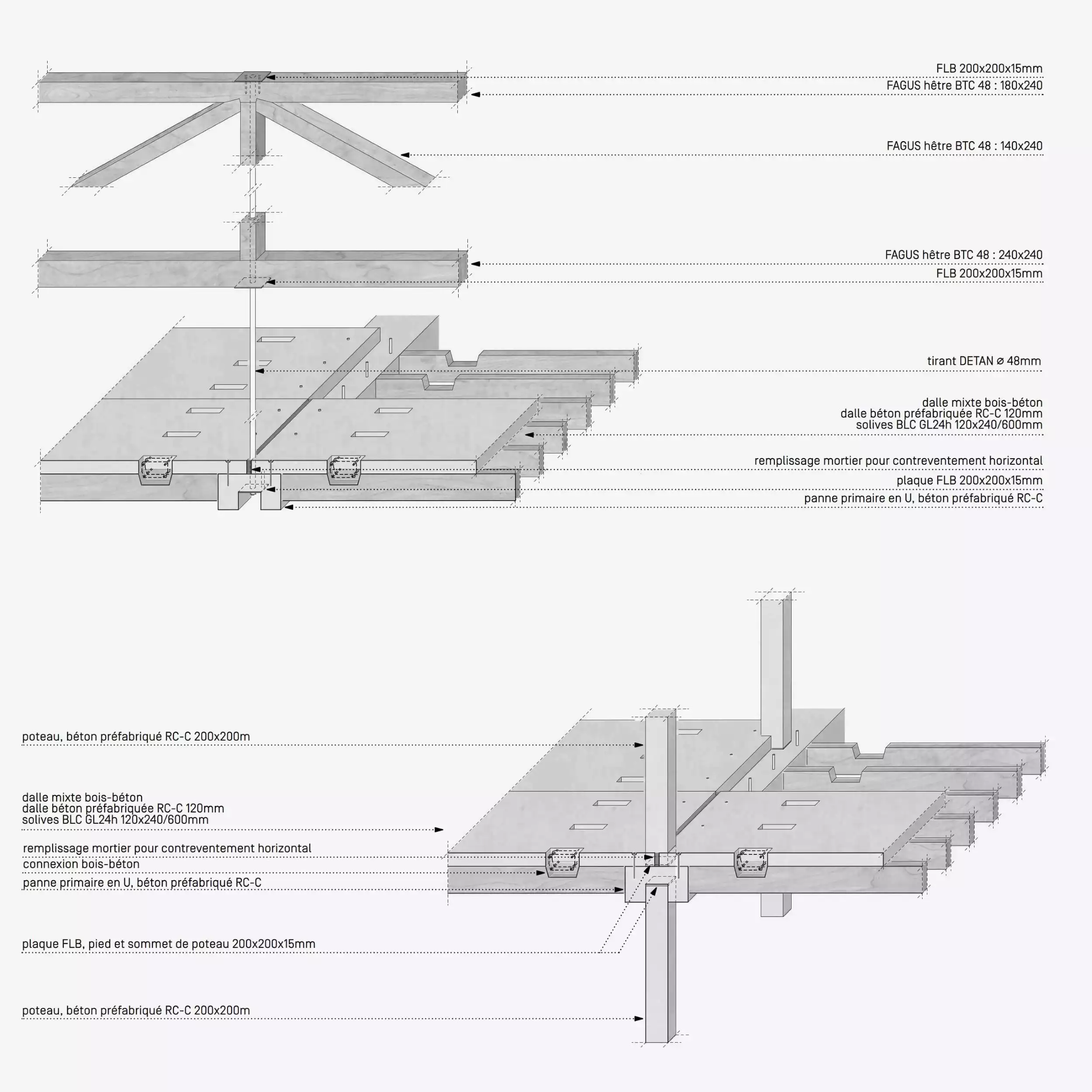

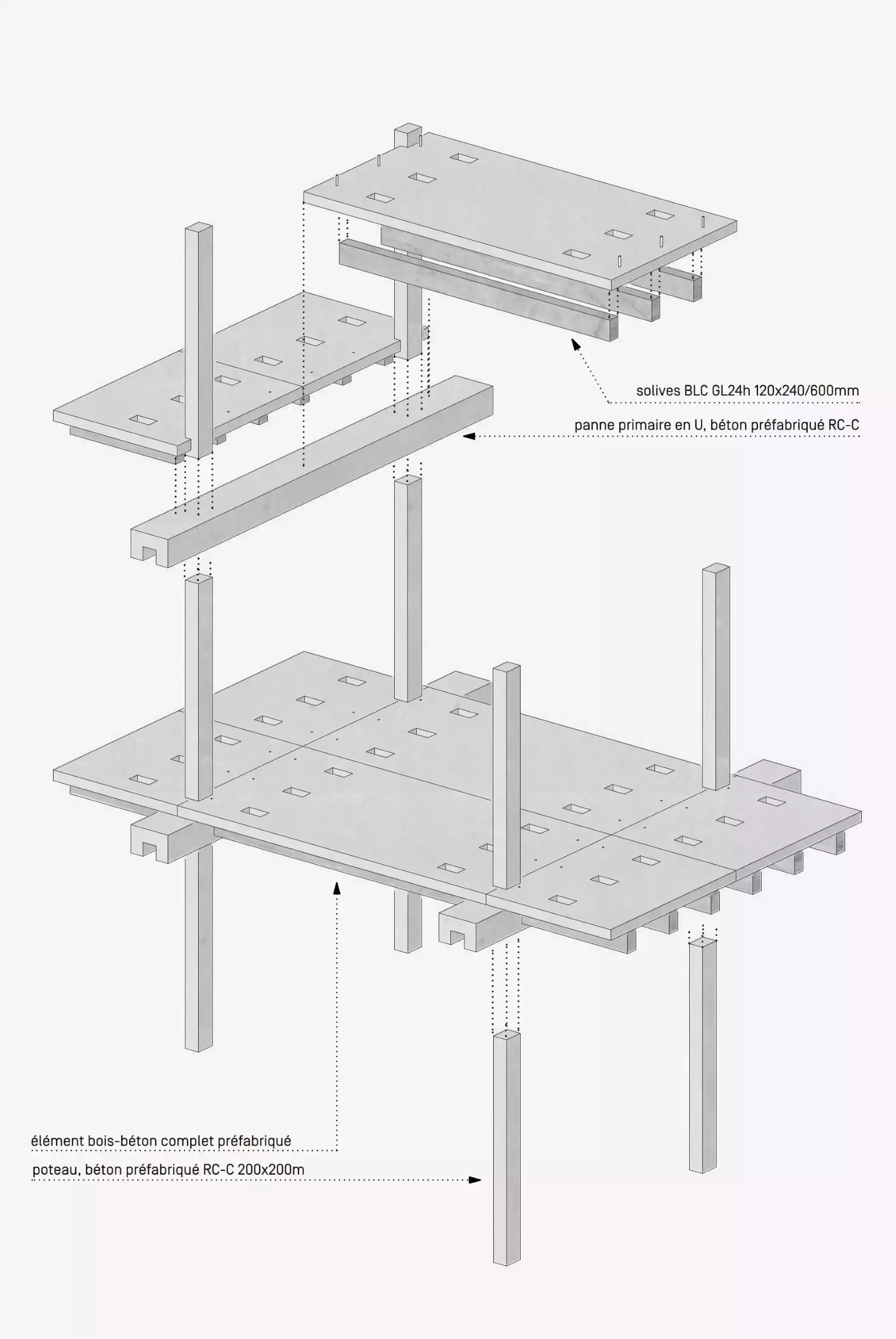

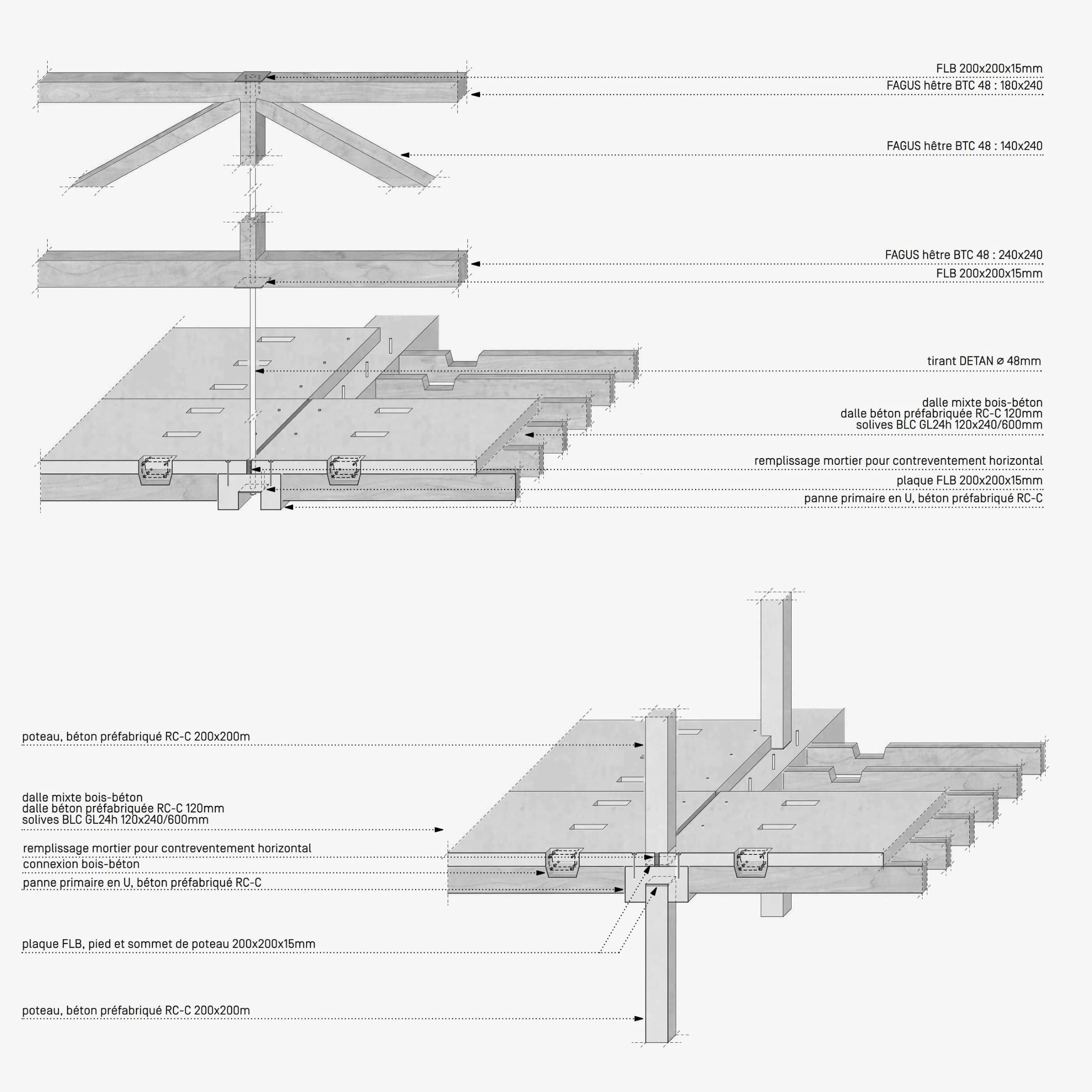

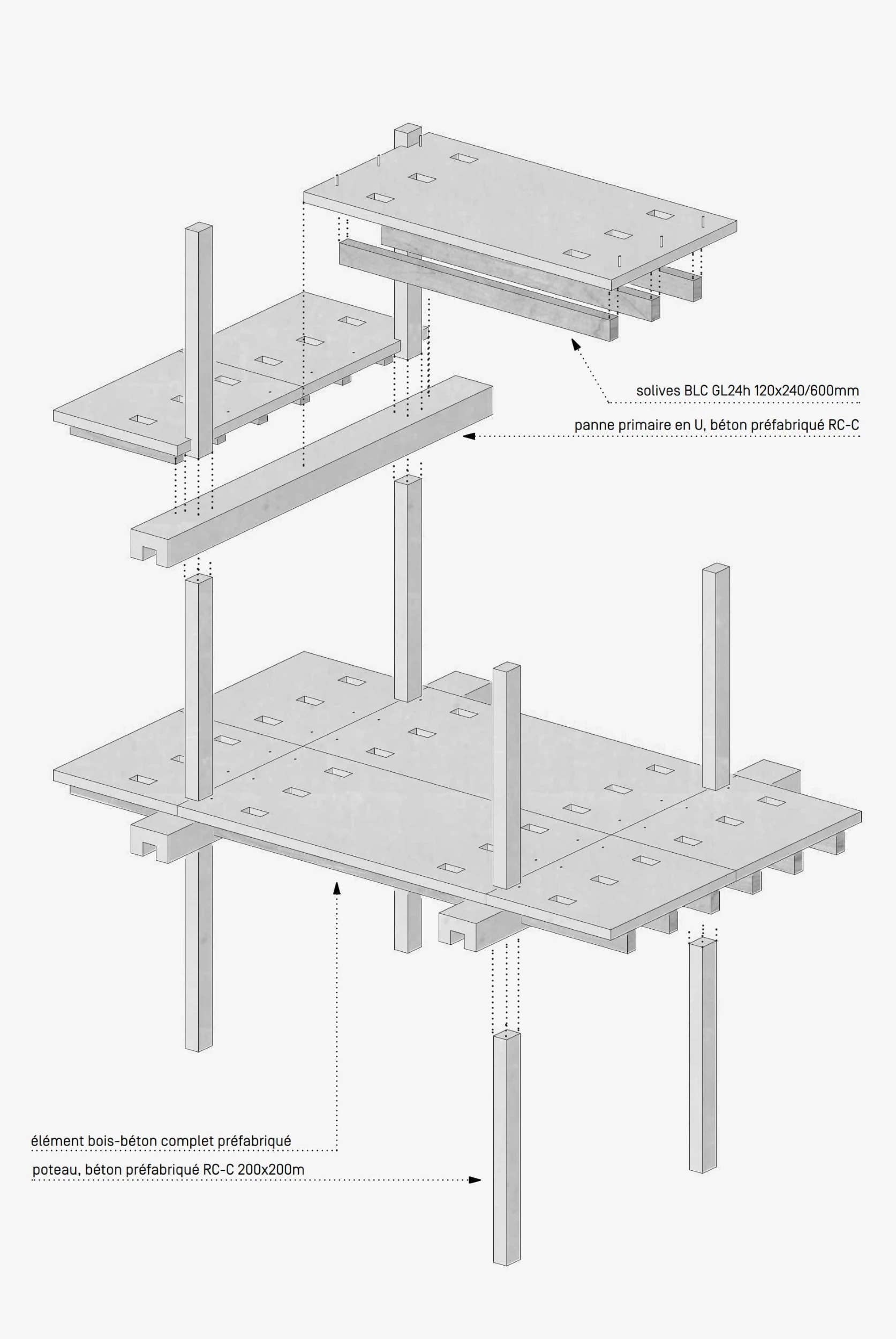

The structure of the project involves prefabricated elements made of timber and concrete, to optimize the use of materials for the wide-spans. In both the parking garage and the barracks, the main columns and beams are made of precast concrete elements and support a composite ceiling. A floor slab rests on GL24h glulam beams. In order to activate the concrete, the bond is created using grouting mortar that encases the reinforcement. As the crowning glory of the park bar, a slender, lightweight steel structure supports the industrial-looking roof made of photovoltaic modules. Should there be an increased need for parking spaces in the next 35 years, this can easily be dismantled and rebuilt with an additional parking deck.

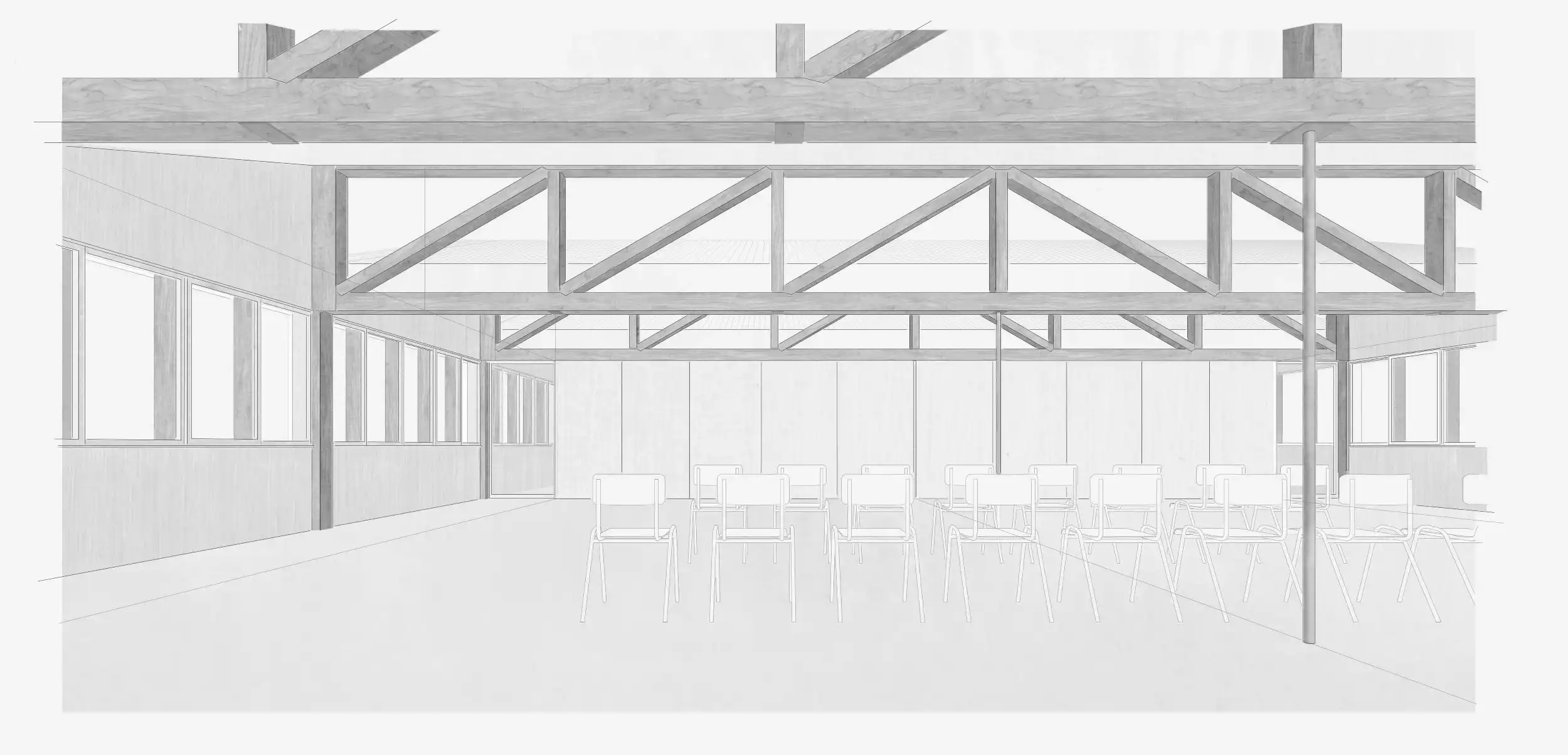

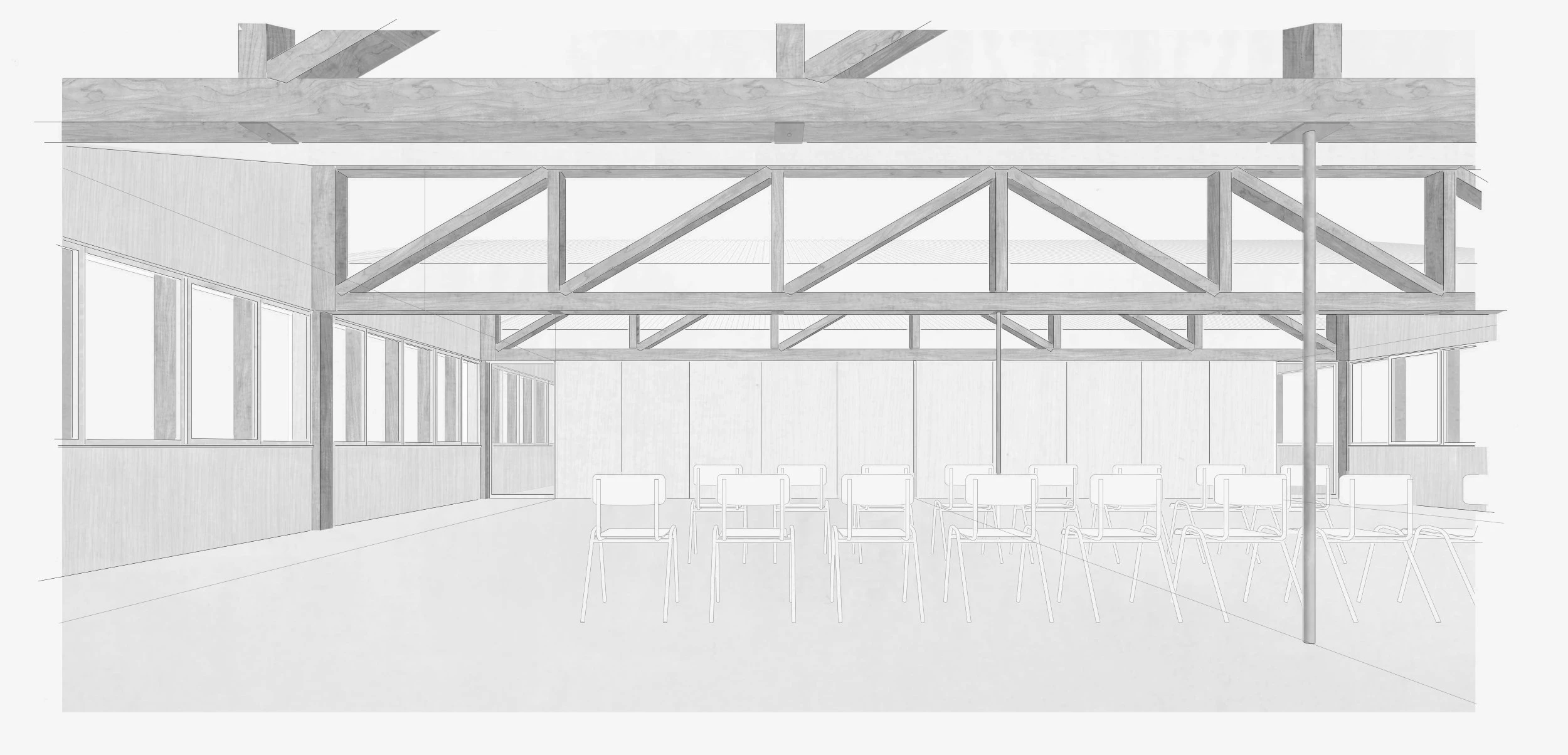

In contrast to the multi-storey parking lot, the timber-concrete composite structure of the barracks is insulated to accommodate a more domestic program. The same principle could be applied to the structure of the multi-storey parking lot in the future, making it reversible and suitable for other programs such as offices, crafts or industry. For its part, the barracks offer the possibility of using the shed roof not only to allow light into the community meeting rooms, but also as a structural height for the installation of a truss. The large span required for the fire department’s vehicle halls is ensured by a slab suspended under the roof.

Above the foundations, all elements are prefabricated and mechanically connected to each other. The prefabrication of these elements is all the more justified as the construction principle is largely repetitive. This leads to cost savings and a high degree of modularity. The beams are bolted between the columns. The floor slab of the composite floor rests directly on the beams and can be attached from above through the recesses provided. All elements can therefore be dismantled, replaced or even reused in the future.

In addition to the economic and practical properties of the construction system described, the project is based on the careful use of resources: use of RC-C recycled concrete with more than 50% recycled aggregate, CEM III cement and Freiburg wood. These elements, which are prefabricated in regional companies, reduce transportation distances and have a better ecological balance. According to a calculation using KBOB values, the composite slab has a 46% reduction in environmental impact compared to a 32 cm thick concrete slab. The reduction in primary energy consumption, gray energy and CO2 emissions is 3%, 43% and 49% respectively. The desire for a simple and architecturally rational structure also enables considerable material savings.